High Temperature of Material

Typical Problems:

-

Hot parts have to be transported with a conveyor belt and therefore a robust running surface is needed

-

How to specifically cool down parts during conveying so that they can be further processed/packaged

Solutions for the Conveyor Technology:

MTF Technik has a long experience in conveying tasks with hot parts. Depending on the task, the following solutions are recommended:

In the plastic injection moulding sector, the part temperatures after demoulding are below 80°C for the most part. This temperature is completely unproblematic for almost all belt types. There is a large selection of different materials here (PVC, PU, felt, polyester, plush, rubber, silicone, etc.), which also meet almost all other requirements (e.g. FDA conformity, surface structure, suitability for use on angled conveyor belts, antistatic properties, oil resistance, etc.).

At temperatures of the parts above 80°C to 100°C, the selection of possible belts for the conveyor belt is already significantly limited. For example, the range of possible belts with FDA certification is reduced. The choice of belts for angled conveyor belts or the possibility of applying cleats or corrugated edges is then also very limited. Running surfaces with PVC or PU surfaces can then generally no longer be used.

In the case of angled conveyor belts or the need for cleats, the choice is then increasingly concentrated on polyester belts such as MTF Belt No. 12. This is very hard-wearing and can be used for a wide range of applications. Felt belts or, in some cases, rubber materials can also be an alternative, but are already clearly limited in terms of the width of their applications.

For continuous temperatures above 120°C to 130°C, silicone belts remain the main alternative. MTF Belt No. 22 (silicone, white) can be used for long-term temperatures up to 180°C. Due to its FDA approval, it is even suitable for medical applications. However, this belt cannot be used on angled conveyor belts and it is also not possible to apply driving cleats, etc.

Belt Types for High Temperatures 1

At even higher temperatures, such as those encountered in die casting, Kevlar felt belts can also be used as a special solution. These are endless woven running blankets that are suitable for contact temperatures of up to 350°C. However, this type of belt can also only be used in the die-casting industry. However, this type of belt can also only be mounted on straight conveyor belts and does not allow the application of carrier cleats, etc.

When specifying the temperature resistance of flexible belts, we are usually talking about continuous temperature resistance. This means, for example, that a belt with a temperature resistance of up to 80°C may be operated permanently in an 80°C oven.

If the temperature of the material being conveyed exceeds 80°C when it hits the belt, it depends to a large extent on the geometry and its thermal conductivity whether a problem can arise. If you imagine a thick-walled cube that lies flat on the belt, this has a completely different influence on the belt than an equally heavy part that, for example, is finely branched or has only punctual points of contact on the belt. In the case of the cube, the temperature of the part is likely to be completely transferred to the belt, whereas this is not the case with the part that rests on points.

In addition, the exposure time also plays a very important role. If, for example, parts are placed on a conveyor belt in order to cool down slowly, the heat transfer to the belt will be correspondingly high. If parts are transported on a short conveyor belt at high belt speed, significantly hotter parts can be transported than the temperature resistance of the belt indicates. During the short contact time, the belt does not heat up and can always cool down sufficiently.

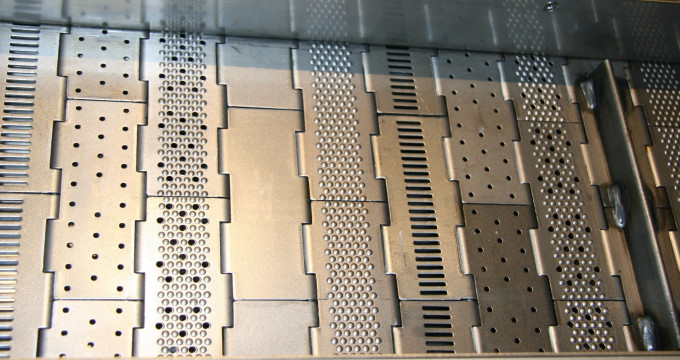

Steel Hinged Plate Conveyor

Particularly in the die-casting sector, the combination of high temperatures and heavy mechanical stress results in requirements that can no longer be met by belt conveyors. Especially when ascending conveying distances require the use of carrier cleats, Steel Hinged Plate Conveyors are usually the best solution.

The steel hinged plates, which are chain-guided on both sides, have a continuous temperature resistance of 300°C and can thus be optimally used as a cooling section. The design of the steel hinged-plate conveyors has integrated spring tensioners that ensure that the tension of the chain is always maintained. In this way, temperature fluctuations and thus elongation effects can also be optimally compensated.

Hinged plates in mild steel and stainless steel as well as many different surfaces allow solutions for many different applications.

Wire Belt Conveyor

Steel Mesh Conveyors are particularly suitable for transporting hot parts when a strong flow of air is required in the conveyor section to cool down the components. The open structure of the steel mesh belts allows air to flow around the conveyed goods in the best possible way and thus cool them down.

This makes such conveyor belts particularly suitable for transporting hot hollow parts, which could not achieve any or sufficient ventilation of the inner structure on a smooth belt or even on steel hinged plates. Here, additional fans below and/or above the conveyor belt can provide additional cooling.

Steel mesh belts can be used for the highest temperature ranges. The contact temperatures of the conveyed material can exceed 1,000°C (only for steel mesh belts without chain guides). For such extreme temperatures, however, the application must be checked carefully in each individual case. Conveyor belt dimensions, belt load, function, etc. play a major role here.

At very high temperatures, the upper run is usually removed via a stainless steel perforated plate; at lower temperatures or with sufficient cooling possibilities, plastic glide bars (high-temperature plastics if required) can also be used.

Depending on the task, very hot parts can also be cooled in a liquid bath.

For this application, MTF Technik offers water conveyor belts in various designs. If the parts are heavier than water, these conveyor belts are usually designed in an angled form. For floating parts, a combination of two straight conveyor belts can also be used. This ensures that the parts are then also pressed under water for a definable time if required - this plays an essential role in so-called conditioning conveyor belts, for example. Here, in addition to cooling, a defined water absorption of the components is desired at the same time.

The water tank is often connected to the cooling circuit of a production machine so that the waste heat is dissipated accordingly and a constant cooling result is achieved. Whether such a solution can be considered often depends on the specific customer requirements or the material properties of the material to be conveyed.

Conveyor Belt with Fan

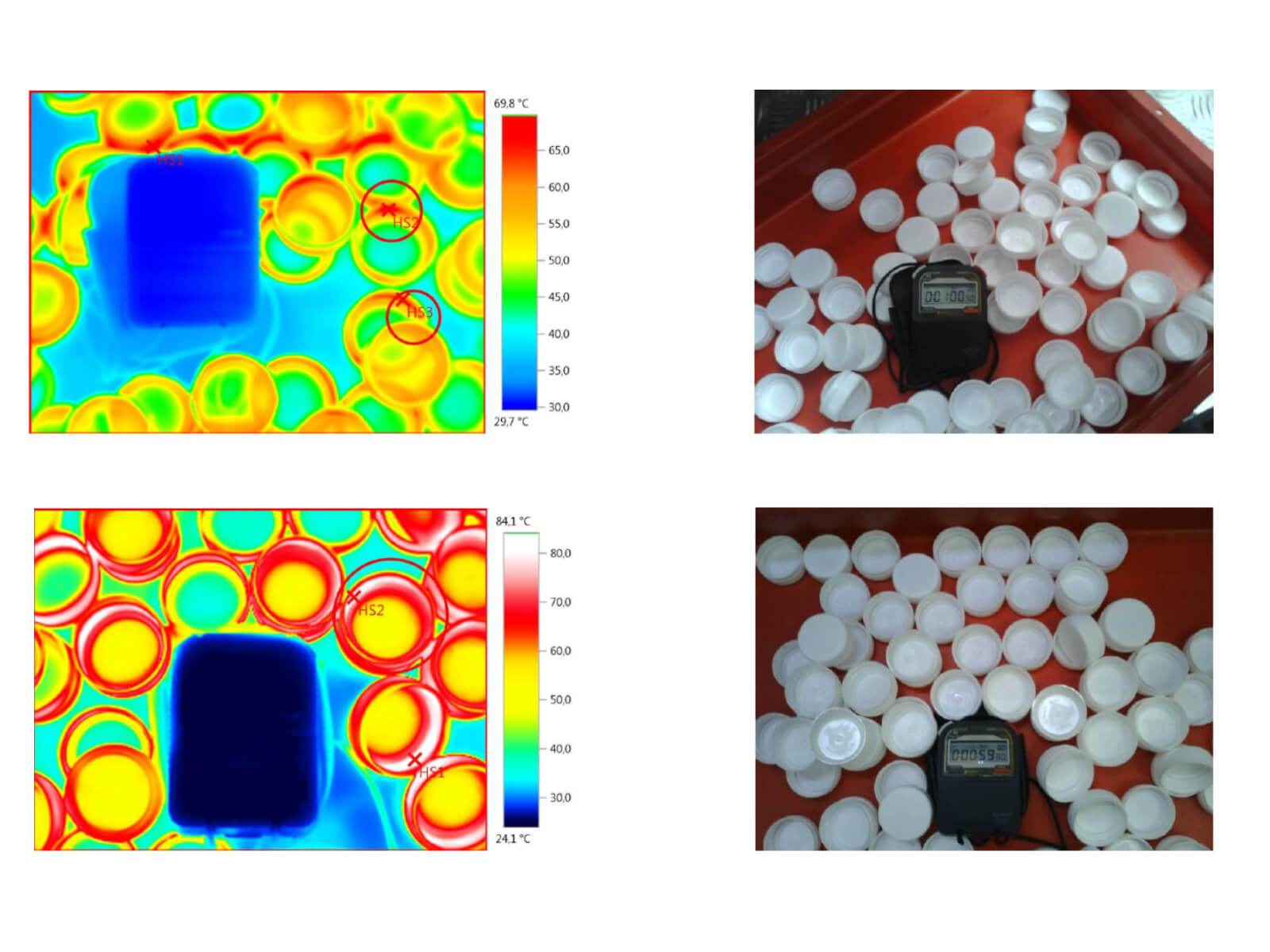

Ventilators are an extremely effective and energy-efficient means of cooling parts. Especially in the production of mass-produced parts such as caps, etc., large quantities of parts are produced within very short cycle times. The parts are often still very warm and soft when they are removed from the mould. To prevent them from deforming under their own weight in the collection container, they must be cooled down quickly.

A fan which blows away the insulating "air cushion" around the parts during the transport process on the conveyor belt is the perfec solution here. The air movement results in a kind of "wind chill effect", which allows the parts to cool down much more quickly.

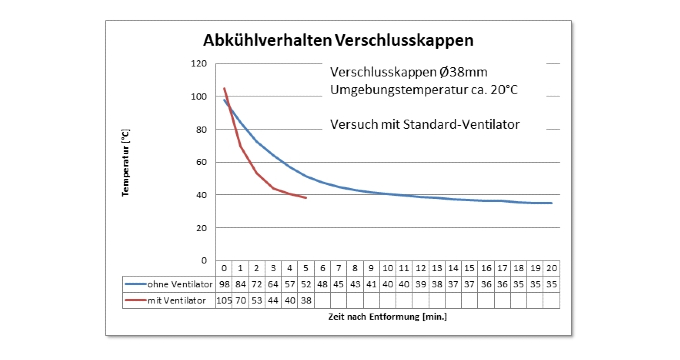

The result of the experiment pictured on the left is that with a standard room fan the part temperature dropped from 105°C to 70°C ( ΔT = 35 °C) one minute after demoulding, whereas the without wind chill effect the temperature only dropped by 14 °C within the same period.

If these measured values are listed in a diagram, the difference becomes clear. Especially directly after demoulding, a fan has a very strong effect. For this reason, MTF Technik usually designs conveyor belts in such cases with on which fans are mounted as directly as possible at the belt infeed. This lowers the part temperature and protects the belt - so even with very hot parts, standard belts can often be used, as the high temperature only affects the running surface for a very short time.

In the example left you see a belt conveyor with several fans integrated in the belt cover. The belt cover forms a kind of tunnel, which ensures that air flows around the parts over a longer distance and can thus dissipate its heat better.

Air Conditioner / Heat Exchanger

Similar to fans, but with controlled temperature control, additional air conditioning units or heat exchangers can shorten the cooling of the components. For this purpose, devices are coupled to the conveyor belt - usually via corresponding pipelines. The cold air is then blown under a belt cover. The heat exchangers can be connected to existing machine cooling circuits, for example, and thus use existing infrastructure.

Compared to fans, this solution has the significant advantage that the temperature of the blown-in air can be better controlled or even kept constant. With fans, only the ambient air is drawn in, i.e. the cooling result is also correspondingly dependent on the ambient temperature. This can lead to problems in summer, for example, in production halls that are not temperature-controlled. This is where air-conditioning units or heat exchangers come into their own.

Separate air-conditioning units (so-called spot coolers) have the disadvantage that, in addition to their cooling capacity, they produce a lot of waste heat. When this is then blown into the production hall, the temperature there rises accordingly and the air-conditioning unit has to work all the harder - there is then a danger of the unit icing up. It is therefore better if the waste heat can be discharged outside the production area.

Due to the relatively high costs of air-conditioning units and heat exchangers, MTF Technik usually recommends first carrying out tests with fans. These are significantly cheaper and often achieve almost equivalent results. Especially with thick-walled plastic parts, it must be taken into account that plastics are poor heat conductors. This means that the core temperature is not cooled down decisively even when cooled air is applied. Here it must be carefully checked whether the investment in an air conditioning unit or heat exchanger and, above all, the running energy costs are justified.

Do you have any further questions? We are available for you by telephone at +49226194310 or info@mtf-technik.de or use our Contact form.