Company News

Congratulations from the IHK Cologne on our 50th anniversary

13.03.2025

Today we had the pleasure of welcoming Mr Michael Sallmann, Head of the Oberberg office of the Cologne Chamber of Industry and Commerce. We were delighted to receive his warm congratulations on our 50th company anniversary! A big thank you to everyone who has accompanied us on this journey and made it possible to reach this milestone. Here's to the next 50 years!

Hardy Schürfeld and the entire team of MTF Technik

MTF Technik was founded 50 years ago today

01.02.2025

As time goes by... MTF Technik celebrates its 50th birthday today 🥂!

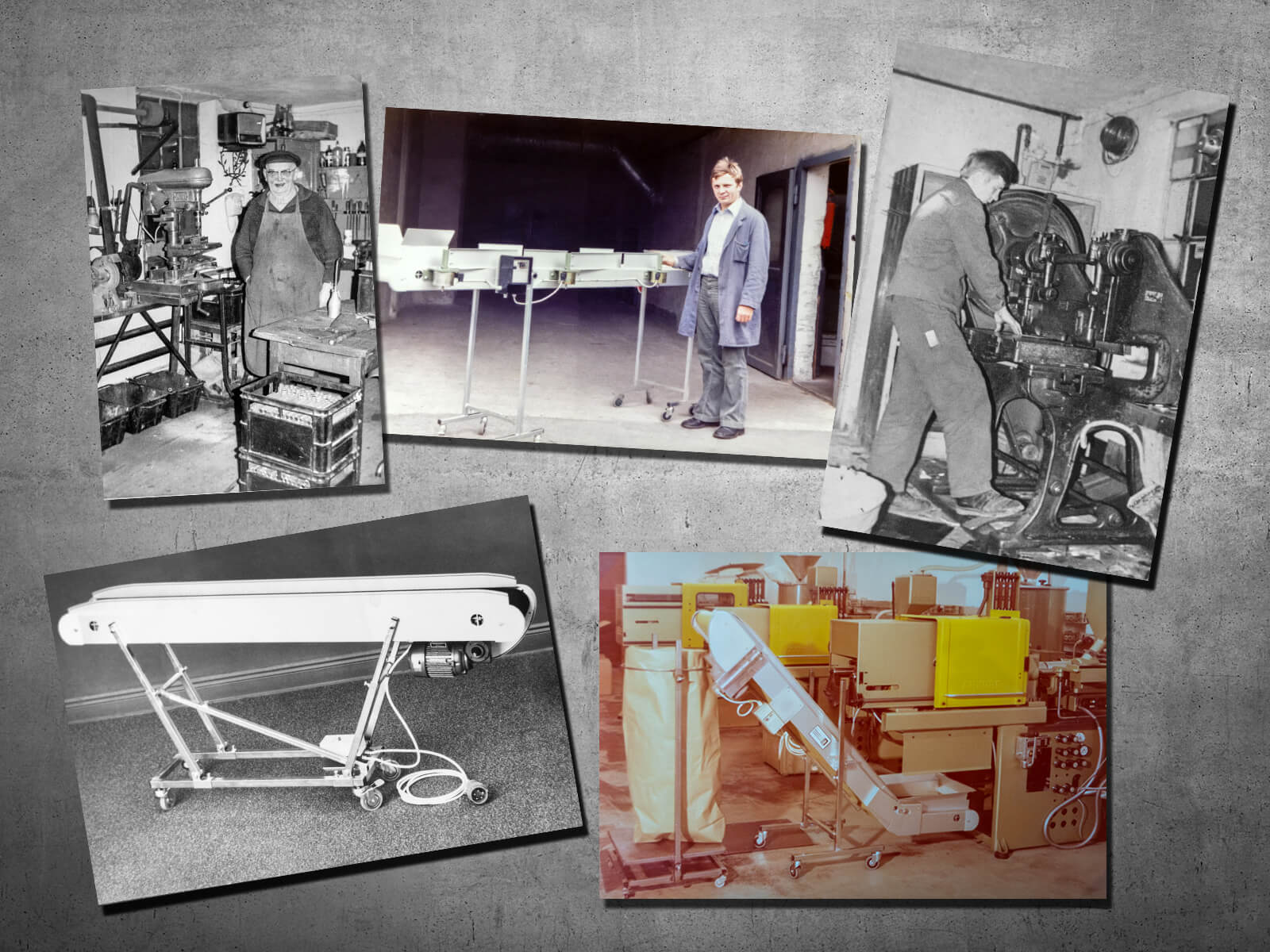

On 1 February 1975, engineer Hans Gert Schürfeld founded the company "MTF" - an acronym for "Metallverarbeitung, Transportgeräte, Förderbänder" - in Bergneustadt.

The inventor and tinkerer planned to develop completely new conveyor belts for the plastics industry that did not yet exist on the market. Always driven by curiosity, drive, diligence, the pursuit of perfection and with an open ear for the requirements and wishes of our customers, he tirelessly developed new products and solutions - from small conveyor belts for transporting components from injection moulding machines, to the development of infinitely adjustable angled conveyor belts, the first patent for the roller separating drum and countless customised projects.

His son, mechanical and industrial engineer Hardy Schürfeld, has continued to develop the company as owner and managing director since 2005. The two engineers have acquired a total of 13 patents and have always adapted to new challenges and new industries. Even today, each device is customised to the individual needs of each customer - for an optimal result in the operational material flow.

MTF Technik - Conveying you to success

Increased Vertical Range of Manufacture with Lathes and Milling Systems

02.12.2024

In November, our production facilities have grown substantially.

We are increasing our vertical range of manufacture and have acquired three CNC lathes, a CNC milling machine, an automatic saw, a rubberising machine and a grooving machine and integrated them into our production.

Our aim here is to take a further step towards greater flexibility and on-time delivery. Turned and milled parts for our conveyor technology, which were previously sourced externally, can now be largely manufactured in-house.

We have also strengthened our production team: a new employee has been hired and our colleagues have been trained on the new machines.

Translated with DeepL.com (free version)

Applications for Materials Handling in focus at FAKUMA Exhibition

21.10.2024

At the international plastics trade fair Fakuma in Friedrichshafen from 15 to 19 October 2024, we have presented numerous applications from the fields of conveyor technology, separation systems and automation.

We are very satisfied with the response at the trade fair given the current economic situation. With pleasure we have welcomed many regular and also new customers at our stand.

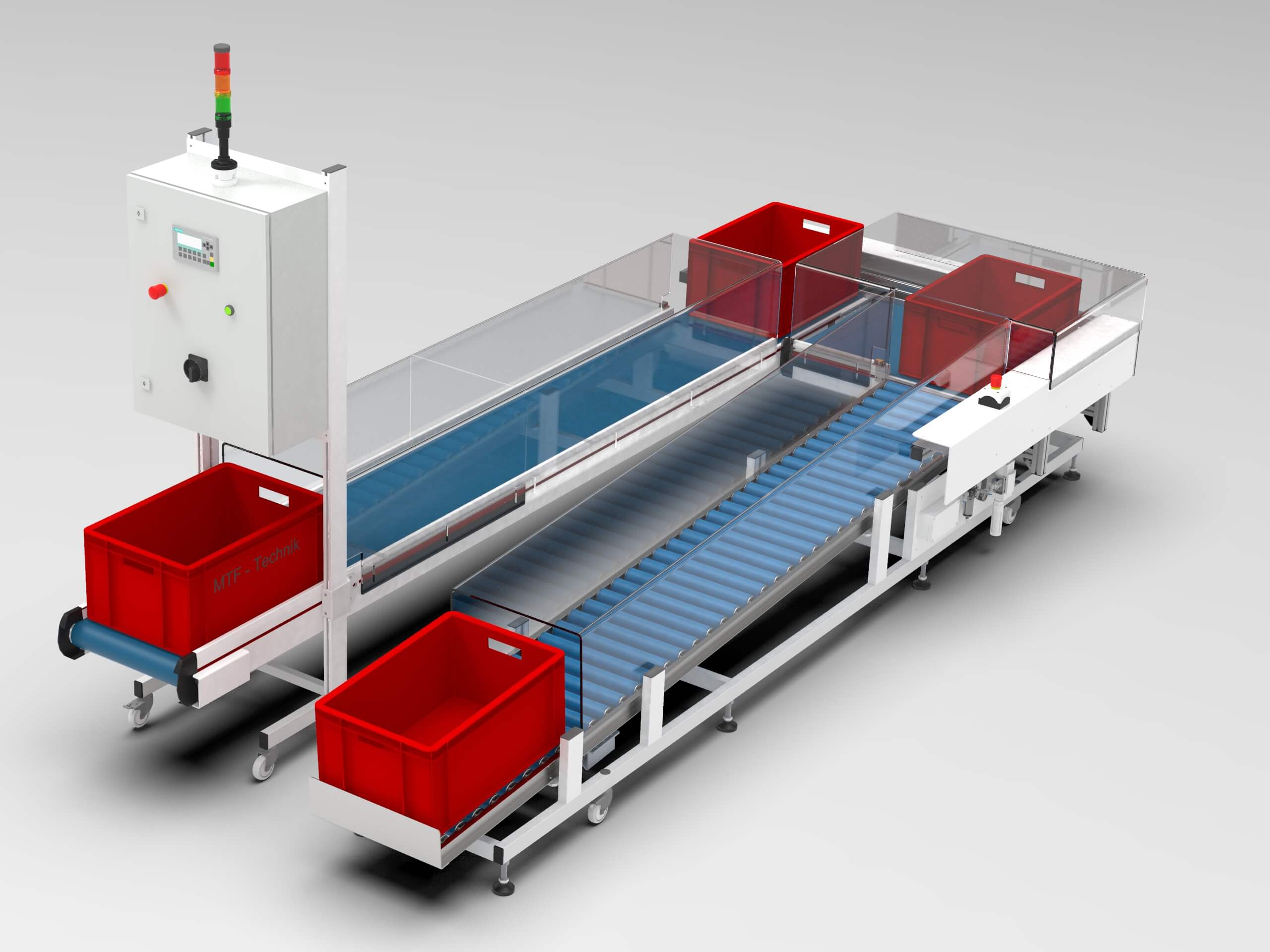

The trend and the need for automation has led to an increased demand for buffer solutions.

There was a great deal of interest in the space-saving lift buffer station, the compact carousel depot station and the floor-level sliding buffer.

The topic of ‘part separation’ also continues to be of central importance for improving productivity in the injection moulding process. Our bestseller, the roller separation drum, and also the rectangular drum for complex part geometries took centre stage here and many inquiries were generated.

We would like to thank all our visitors and we are looking forward to the upcoming projects.

See you again next year at K2025!

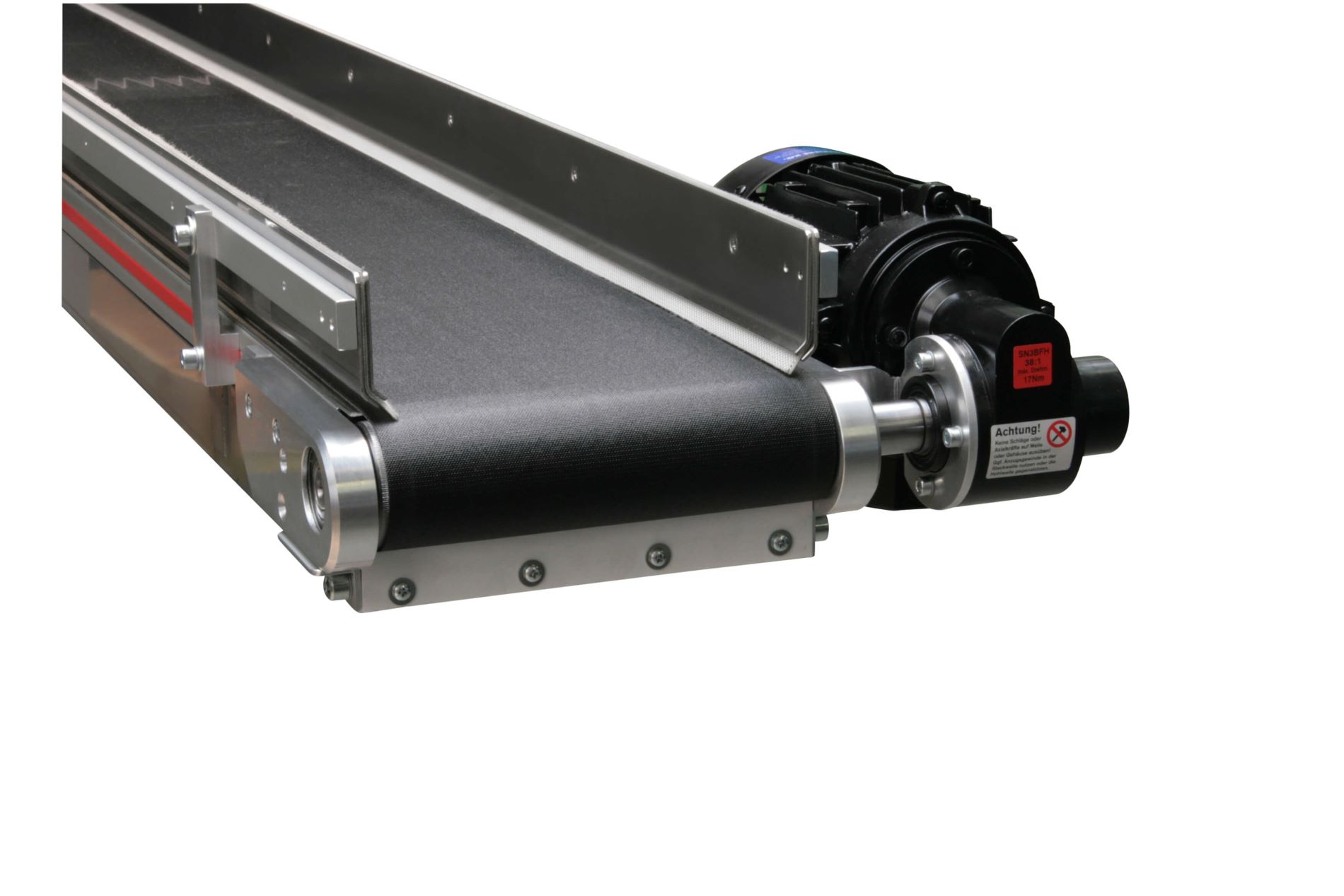

Flexible Conveyor Belts for Pharmaceutical Production

08.10.2024

Large order for small conveyors:

25 IL-IE 010 small belt conveyors have been produced and are currently being prepared for dispatch to a renowned pharmaceutical company in Germany. These small belt conveyors are used to transport medicines from a packaging machine through a labelling system.

These conveyors are particularly flexible to use. Due to the gas pressure column, they can be easily adjusted in height and inclination by one person. They can also be used in different transfer situations as they have small deflection roller diameters and an optimised outer width/useful width ratio. This means that even small packages can be transferred without any problems.

You need more information about our small conveyors? Please go to our product site.

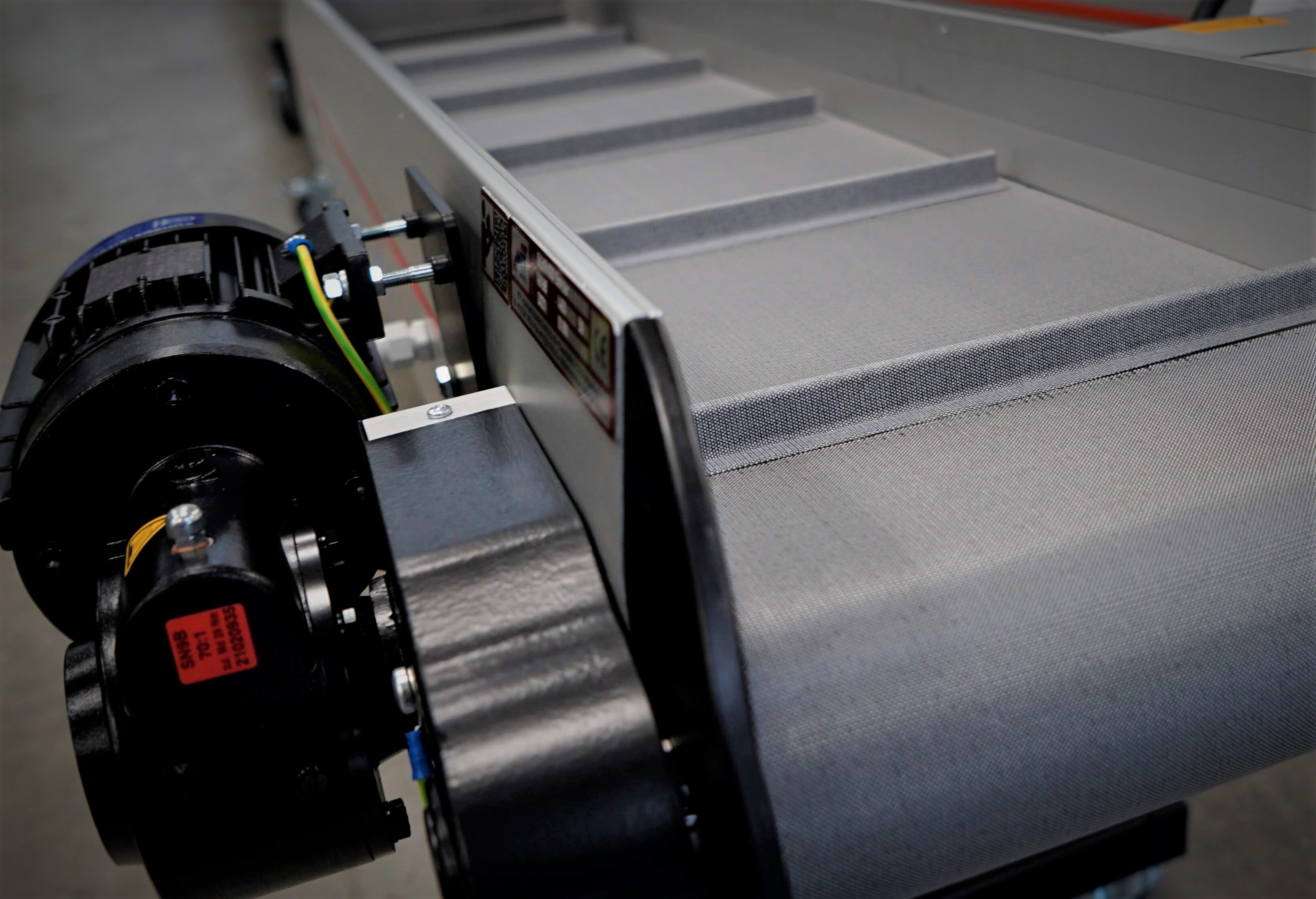

MTF-Quality: 36-year-old Conveyor Belt is Back in Use

09.10.2024

Turning old into new:

This MTF conveyor belt was manufactured in 1988 and has therefore been in reliable use for 36 years. It was now in need of repair and therefore was sent to MTF Technik .

The necessary spare parts were in stock and the belt was remanufactured to order.

All in all, this was a very cost-effective repair.

Now, the conveyor is fit for the next 36 years in operation - and thus a good example for product sustainability.

MTF-Advisor to Efficient Buffering of Material

05.07.2024

Our new article of the "MTF Advisor" deals with the various options for efficiently distributing and buffering material.

MTF Technik offers a wide range of rotary tables for short-term parts buffering, box changers and conveyor belt systems with lift.

Find out which buffer systems are best suited for your application - including a checklist: To Advisor for Buffering Systems.

MTF Technik at Plastpol 2024 in Kielce/Poland

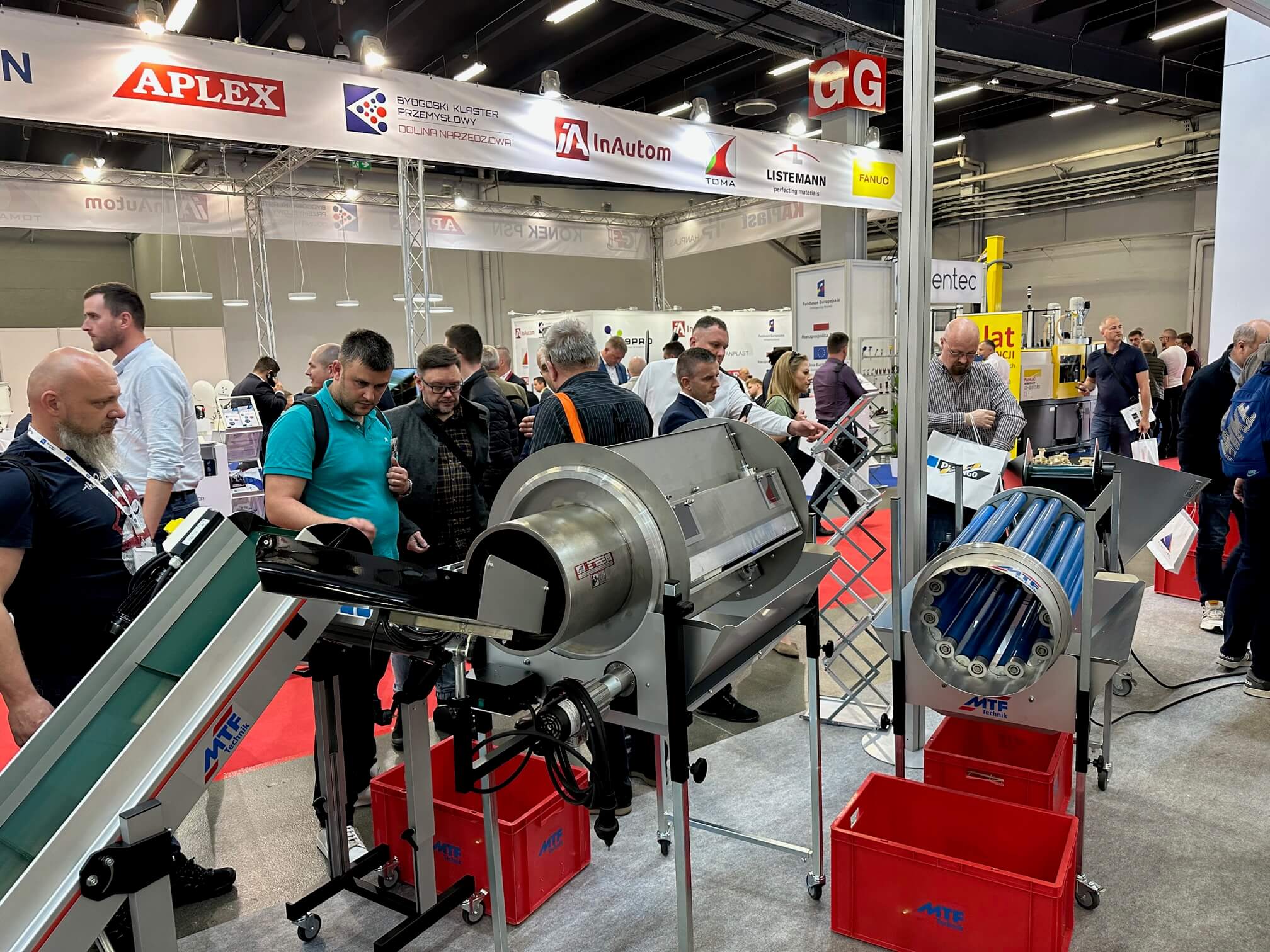

27.05.2024

Our representative PlastLine successfully presented the MTF Technik portfolio at this year's PLASTPOL in Kielce (21-24 May 2024). Our consultant at the trade fair registered particular interest in the topic of parts separation.

We would like to thank PlastLine for the professional presentation and are delighted with the positive response.

Please contact PlastLine for further information about our products .

ECM Industries (CPM) is new Sales Partner in Denmark

13.05.2024

MTF Technik is represented in Denmark by our new sales partner ECM Industries via the Brand CPM – PART OF ECM.

Please contact Mr Jørn K. Nielsen if you have any questions about our conveyor technology.

We are looking forward to a prosperous co-operation.

CPM - PART OF ECM

Contakt: Mr. Jørn K. Nielsen

Petersmindevej 12

DK-6000 Kolding

Phone: +45 31 539688

CPM@ecm.dk

ECM INDUSTRIES A/S

Runddelen 11, Øster Starup

DK- 6040 Egtved

https://www.ecm.dk

Photovoltaic system of the company building in operation

15.03.2024

DThis week, the photovoltaic system with 100kWp output and 22kW storage was put into operation on our company building. We are pleased to contribute to the avoidance of CO² emissions and thus make a further contribution to sustainability.

In addition, the components of the system are from German manufacturers and the installation was carried out by a local service provider - the motto "Made in Germany" also applies here.

We will use the self-generated electricity primarily for the production and maintenance of the building. The installed energy monitoring system is used to continuously discover further potential savings. Furthermore

2 wallboxes have been installed, which our team can use to charge their vehicles.

MTF-Advisor: Efficient Separation of Components

01.12.2023

The latest article in our advisor deals with the options for efficient separation of sprue and usable part.

Here you can find out which separation systems are best suited for which application:

🎬 FAKUMA Review: Integrated Solutions for Materials Handling

23.10.2023

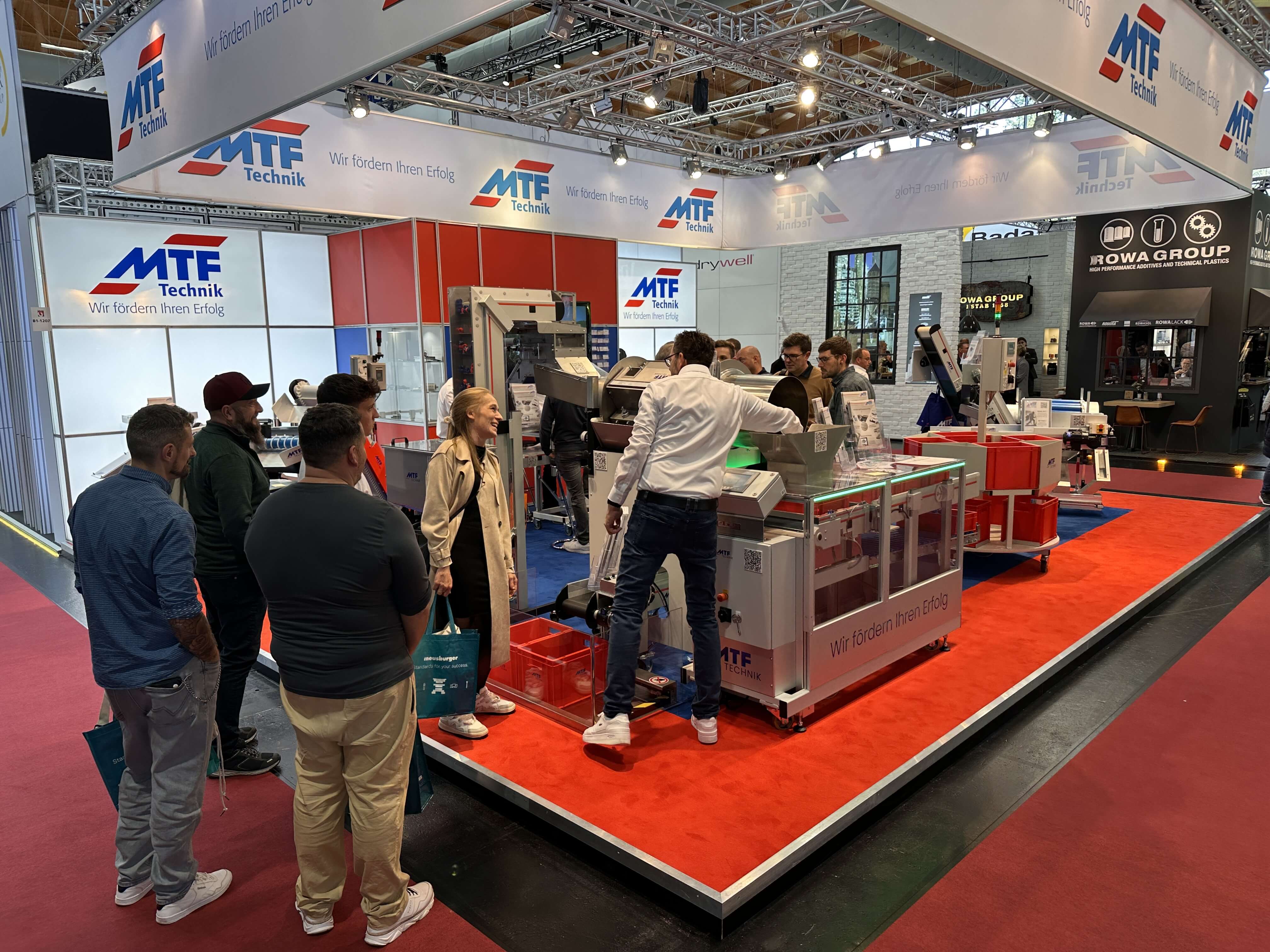

At the FAKUMA international plastics trade fair from 17 to 21 October 2023 in Friedrichshafen (Germany), MTF Technik presented numerous innovative applications for the internal material flow.

Hier you can watch the exhibition video.

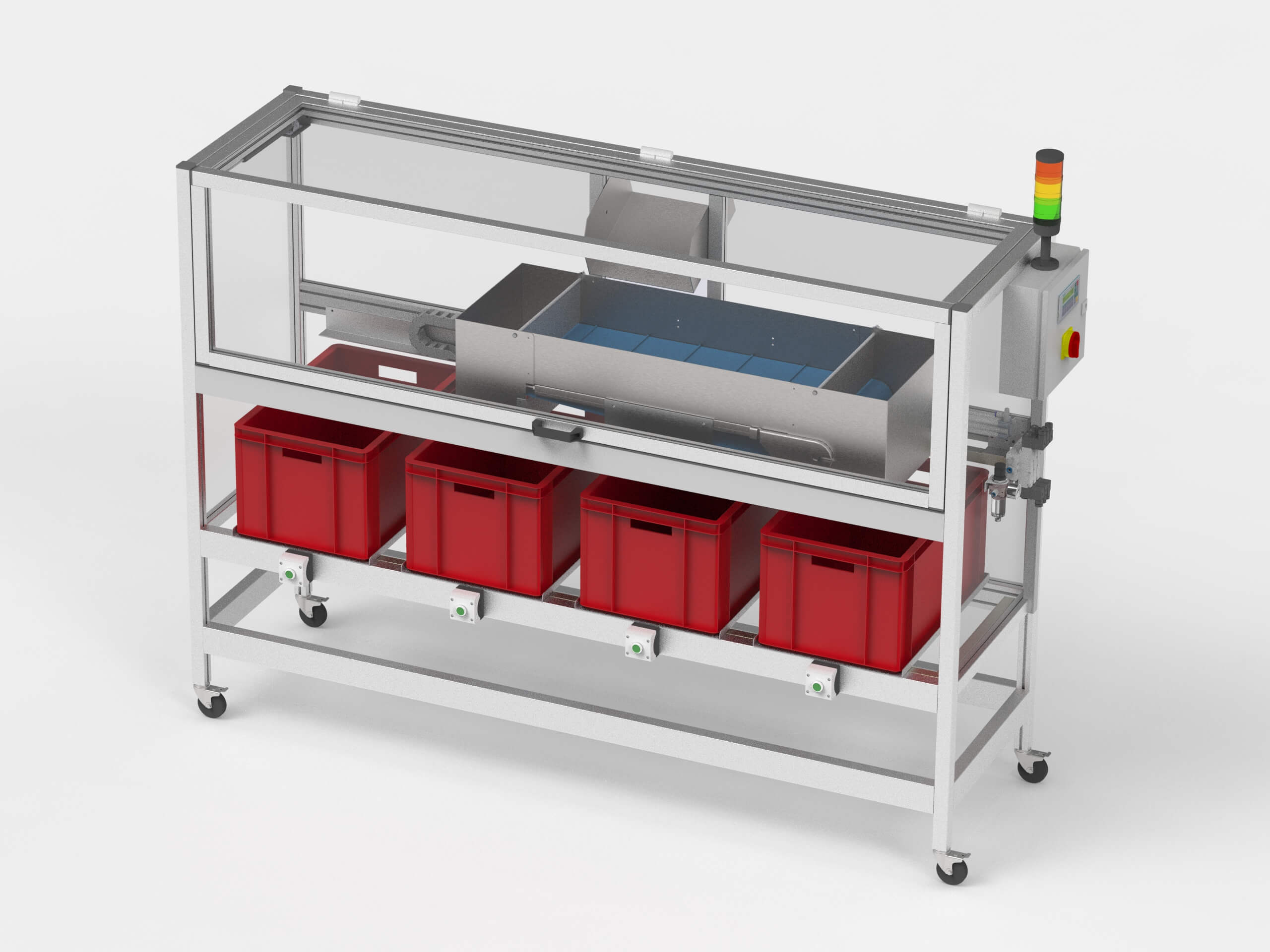

In accordance with the maxim "Space-saving solutions with optimum functionality", visitors were able to see for themselves the latest new developments in the area of parts buffering, such as a compact buffer system with load cell, a floor-deep sliding buffer, a space-saving pick-up system for container buffering, as well as a dosing conveyor angled at 90°. The rectangular separating drum integrated into the discharge was also of great interest.

All in all, it can be observed that the majority of enquiries are increasingly moving from simple conveyor belts to integrated solutions for material handling, such as buffer systems. Product innovations and further developments of well-known devices were predominantly in demand.

Another focus this year was on maintaining contact with our customers. We were able to welcome a large number of existing customers, also together with our representatives, to our stand and hold many interesting discussions regarding upcoming projects.

We say "thank you" to all our visitors and look forward to challenging new projects.

Your MTF-team

Recent Press Releases (Germany):

K-Aktuell, 21.10.2023

Plasticker, 25.08.2023

K-Zeitung, 28.08.2023

% Special Offers for Stock Devices %

23.11.2023

We strongly recommend to browse to Service / Special Offers on our website or simply click onto the right tab with the percentage symbol:

There you will find several demonstration devices for conveying and automation at special offer.

Your benefits:

- very good / mint condition of devices

- available at short-term notice

- favourable prices

First come, first served!

We are at your disposal for further information via phone number +49 2261 94 31-0. Or simply contact us by e-mail to info@mtf-technik.de.

Optimised Energetic Efficiency of MTF-Separators

17.11.2023

For our screw separators, such as the MSL 600 Multi-Separator and the SAL 600 Separating Attachment, we now use significantly more economical and even safer motors. By changing the wattage we achieve energy savings of 43% compared to the previous model while maintaining the performance level.

We also score highly in a competitive comparison with significant savings in costs of operation - with the common use of 90 watt motors, this results in savings of over 300 euros with 2-shift operation and an calculated economic service life of 7 years.

The motor speed can also be set from 8 to 140 revolutions thanks to the optimised reduction ratio, making the appliance even more versatile.

You can find more information about our stand-alone separators here and about our separating attachments here.

Sustainability is our corporate philosophy

06.09.2023

"Sustainability" is not just a buzzword at MTF Technik, but has always been part of the corporate philosophy. i.e.:

-

Local sourcing - 96% of the purchased material volume comes from Germany and the rest from neighbouring countries

-

The complete engineering and assembly and production takes place in Bergneustadt/Germany

-

Consistent design of the devices for long durability and availability of spare parts for old devices (up to almost 50 years!)

-

Customer loyalty - 3/4 of our customers have been working regularly with MTF Technik for more than 10 years, around 2/3 even for more than 25 years

Measures for better energy efficiency in company

08.08.2023

MTF Technik has implemented various measures to reduce energy consumption following a comprehensive energy analysis to identify potential savings:

e.g.

- Modernisation of existing pumps on heating and ventilation systems

- Complete conversion of the lighting to LED technology

- Optimisation of the heating and ventilation system

In addition, a 100kWp photovoltaic system was commissioned. This should be ready for operation at the start of 2024 and therewith we will be able to cover a large part of our energy demand.

Everyone benefits from this - we save costs and make a contribution to climate protection!

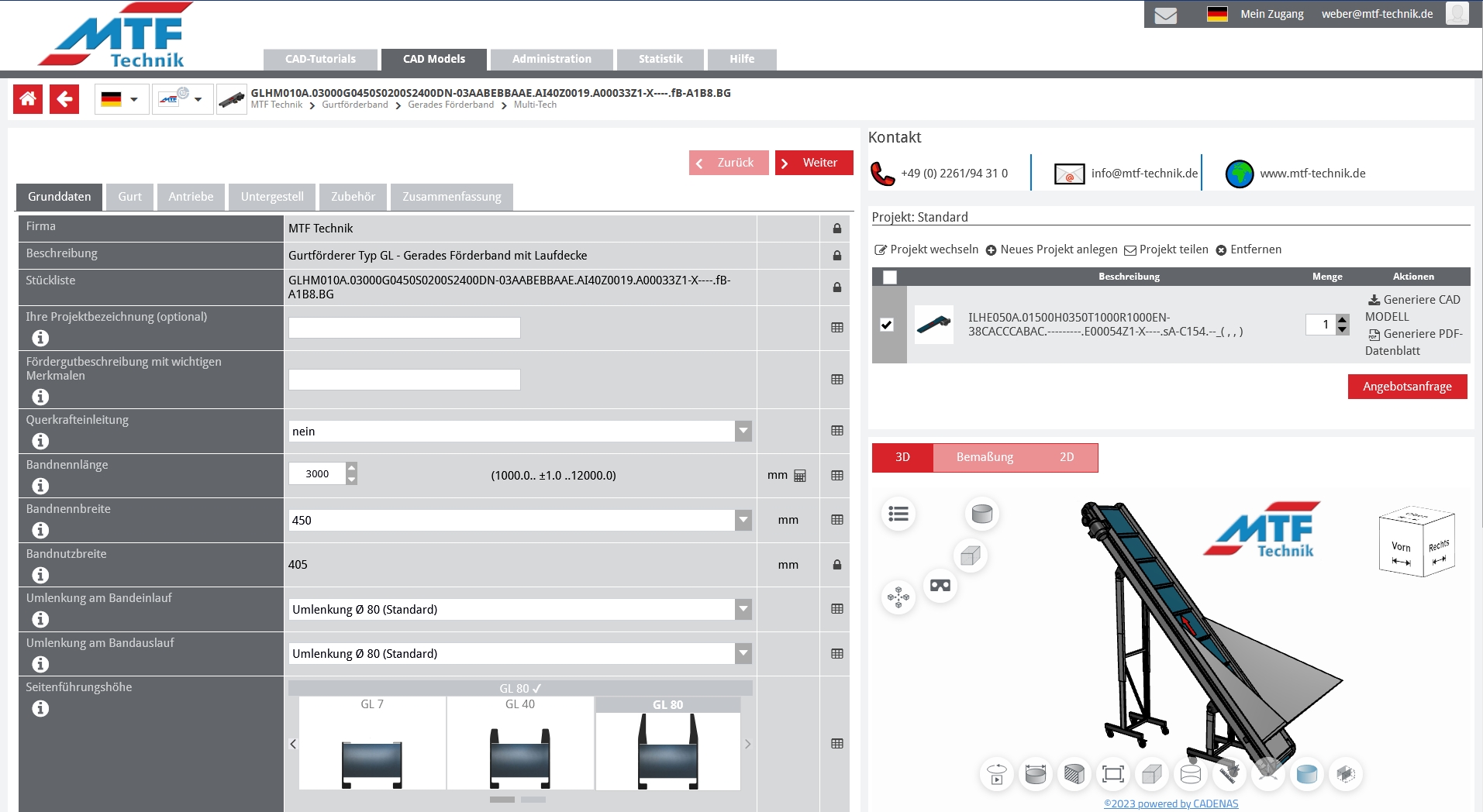

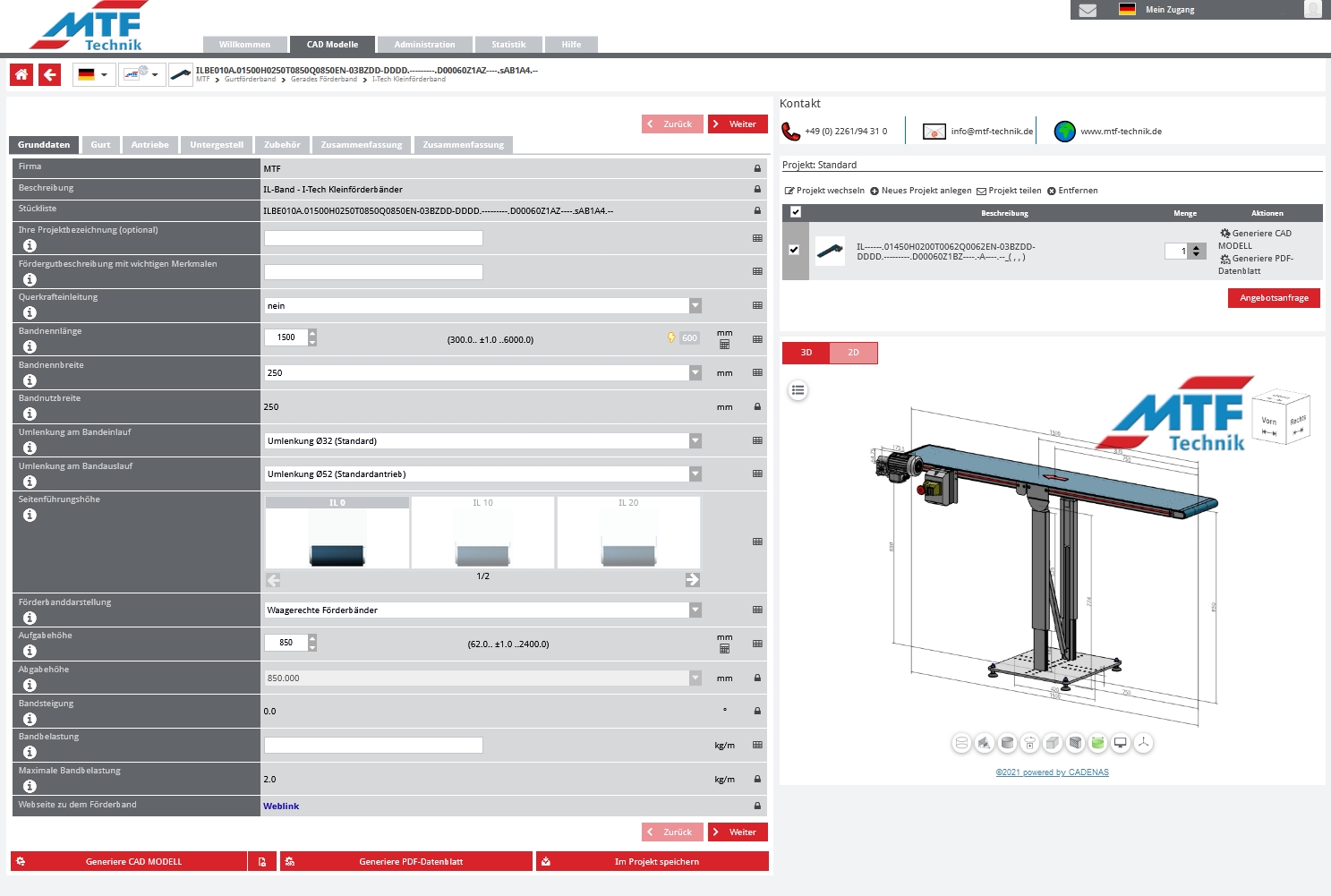

MTF Conveyor Configurator for easy layout planning

24.07.2023

The MTF Conveyor Configurator has been established as a user-friendly tool for the individual design of conveyor – in 2022 it was already used 9,000 times for configuration. Herewith, the user can design straight conveyor belts of different sizes (Multi-Tech/I-Tech versions) according to his requirements very quickly and free of any charge. The tool is constantly updated and has just been optimised with regard to the applicable drive units.

All the desired characteristics of a conveyor belt, such as dimensions, infeed and discharge height, belt specifications, drive unit, base frame and some extras can be selected step by step - the program thus includes thousands of possible combinations. The configurator leads the user interactively through the individual stages of the program. If required, a help function is available for each input field. In addition, a plausibility check is carried out parallelly.

After configuration, the designer immediately sees the result of his planning. He receives both a complete 3D drawing in all common CAD formats and a PDF data sheet including all relevant dimensions and specifications, as well as a preview drawing in which the model can be rotated or sections can be created, for example. This data sheet serves as the information basis for a quick quotation by MTF Technik and thus also enables the desired device to be delivered at short notice.

Why not try it and see for yourself? Link to Conveyor Configurator

The trade media in Germany currently reports on the configurator:

Cadenas Software, 20.07.23

Autocad Magazin, 27.06.23

Coscollola presented MTF Technik at Equiplast in Barcelona

05.06.2023

Our Spanish sales partner Coscollola S.A. successfully presented an excerpt from our conveyor programme at this year's EQUIPLAST trade fair in Barcelona at the end of May. As a still very current topic, the separation, e.g. of sprue and injection moulded parts by means of a separation drum was illustrated. Many visitors were able to convince themselves of the functionality and quality of our products and various inquiries were generated.

Further information: Coscollola Website

Current press report about MTF Technik in conveying and separation (Spanish):

Interempresas Magazine, 25.05.2023

News from the exhibition PLASTPOL in Kielce, Poland

26.05.2023

MTF Technik was represented at PLASTPOL on the stand of the Polish representative Plast Line with a larger selection of conveyor and separator combinations, which were in operation on site. These units attracted the attention of visitors due to their functionality and consequently, various enquiries were generated.

We thank Plast Line for this comprehensive presentation and look forward to further cooperation.

Further information here:

Plast Line Company

PLASTPOL Website

Response to MIS International Industrial Fair in Celje/Slovenia

24.04.2023

MTF Technik was presented by our sales partner TopTeh at this important industrial fair for Southeast Europe. Our sales team was pleased with the great response of the fair - and it seems that investment activity is increasing again. Many visitors were very interested in the functionality of our equipment, a PZ separating drum together with a dosing conveyor, which were in operation for demonstration purposes.

We are very much looking forward to the upcoming projects!

For more information, please contact our sales partner Top Teh for the region Slovenia, Croatia and Serbia.

Fire protection training for safety at work

03.03.2023

Today, there was a training for fire protection and evacuation assistants at MTF Technik, in order to guarantee the safety of people and building installations in the event of an emergency... And it was also fun!

International Sales Training at MTF Technik

10.02.2023

This week, a three-day sales training for our foreign sales partners took place in Bergneustadt. Hardy Schürfeld informed about the special product advantages and functionalities of the current product range of MTF Technik in the field of conveying, separating and automation and showed the production facilities. We thank the participants from our partners and wish them continued success:

Hans Claussen, Norway

Storker Kft, Hungary

Plast Line, Poland

FIT Plasturgie, France

Polmak Plastik , Turkey

The MTF Team

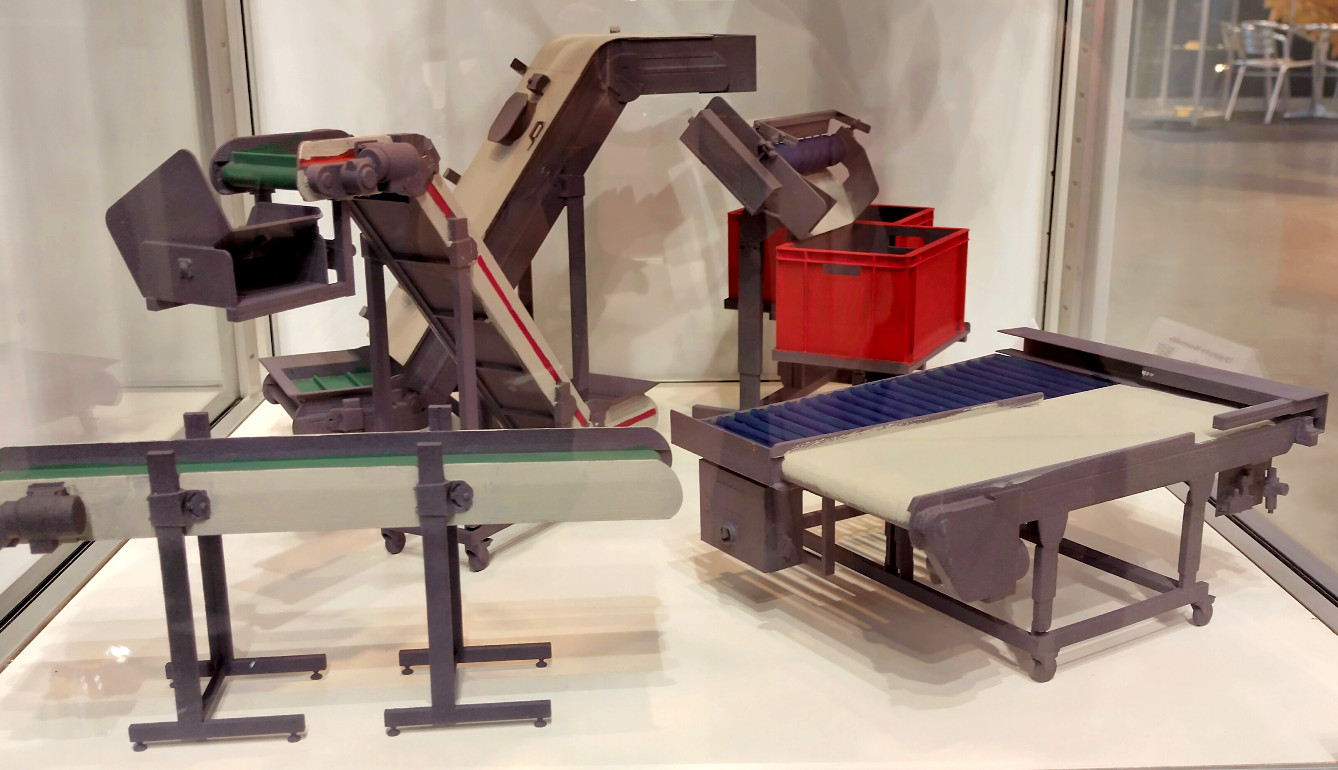

MTF Technik was successfully presented at the Swiss Plastics 2023

20.01.2023

Our Swiss sales agency HATAG AG pursued an innovative trade fair presentation at the SWISS Plastics trade fair in Lucerne, where it exhibited miniature 3D-models of, e.g. MTF-conveyor belts, and automation and separation equipment. This original presentation attracted the attention of the numerous visitors and several new customers were recruited.

More Information:

HATAG Handel und Technik AG Website FR

Swiss Plastics Expo Website FR

New Sales Agency for MTF Technik in Turkey

14.11.2022

MTF Technik is now represented again in Turkey. The company POLMAK PLASTIK in Istanbul has been successfully representing international brands from the plastics industry for several years and now also offers our portfolio of conveyor belts, separation systems and automation.

POLMAK PLASTIK

Kimya Makina San. ve Tic. Ltd. Şti.

İkitelli OSB Demirciler San.Sitesi

E-2 Blok 420

34490 Basaksehir - Istanbul

Turkey

You can reach POLMAK PLASTIK by phone +90 216 4928510 or by e-mail: info@polmakplastik.com.

We are looking forward to a successful partnership!

Comeback at the Trade Fair K 2022 in Düsseldorf

28.10.2022

MTF Technik gives a very positive summary of the course of the international plastics trade fair K 2022 in Düsseldorf, where presented our well-known bestsellers and further developments in conveying technology.

Despite the persistently tense global economic situation, we were able to record numerous visitors who were in a positive mood and would like to make new investments in their machinery. Many visitors from Germany and abroad were interested in our product range and we registered numerous new contacts.

The regular customers and also the domestic and foreign sales partners of MTF Technik consistently gave positive feedback on our applications and emphasised the quality and reliability of our equipment, which is an important aspect especially in times of crisis.

The topic of recycling and circular economy was present on all sides and was taken up by an angled conveyor belt with various options for metal detection. In addition, our separating and buffer solutions for automating production were in particularly high demand.

New customers were particularly interested in the special demonstration units, where we were able to show a variety of different belts, drive units and underframe variants as well as different equipment options.

Last but not least, our separation demonstration with a space-saving 90° dosing conveyor, which feeds plastic parts via a distributor switch into a rectangular drum and then buffers them in a pick-up caroussel, was a real visitor magnet.

We would like to thank you very much for the interest shown in us and look forward to all new projects with our customers.

International press articles (examples):

https://www.izaro.com/sistemas-de-distribucion-y-estaciones-intermedias-de-mtf-technik/c-1663922681/

MTF Technik Continues to Invest in Machinery

23.05.2022

We have just put our new press brake into operation. With the new machine, we are even more flexible when bending difficult parts and thus take another big step in quality, flexibility and productivity.

Support for the Victims in Ukraine

23.03.2022

The Russian war of aggression on Ukraine makes us very dismayed and concerned. We have to witness how the plight of the people on the ground is increasing day by day. Therefore, we as a company are using various ways to help.

On the one hand, we have donated a large amount to the non-profit organisation Aktionsbündnis Katastrophenhilfe.

On the other hand, our employees have handed over various private donations in kind to a local initiative in Bergneustadt, which regularly carries out transports to the crisis area.

Perhaps we can encourage others to support the victims of the war - and to support the numerous aid organisations and local initiatives.

The Company MTF Technik celebrates 47th Birthday

01.02.2022

MTF Technik celebrates its 47th anniversary today!

The company was founded by mechanical engineer Hans Gert Schürfeld in Bergneustadt on 1st February 1975. Even back then it was called "MTF" - this German abbreviation stands for "metal processing, transport equipment, conveyor belts".

Initially focussing on the plastics industry, innovative solutions in conveyor technology were developed and various patents were acquired. Almost continuously, MTF Technik has been achieving steady growth and today is a successful family business in the 2nd generation with around 50 employees and numerous representatives worldwide.

Congratulations and many thanks to the entire former and current team, which has made this success possible.

Advisor for Cleanroom Production, Food and Medical Technology

04.11.2021

When conveyor technology is to be used under cleanroom conditions, special challenges arise for the design of the equipment. In the current article of the MTF Advisor, we deal with this topic and show proven solutions.

Are you curious?

You can find our guidebook here: MTF Technik | Service | Advisor

Product configurator is now available for I-Tech small conveyors

13.09.2021

The conveyor belt specialist MTF Technik has expanded its online product configurator. From now on, customers can - in addition to the straight Multi-Tech conveyor belts - also design and compose straight Small Conveyor Belts of the "I-Tech" type according to their requirements.

I-Tech conveyor belts are often required in case of restricted available space, as they are predominantly integrated into machines and tool shafts. In this context, it is particularly important to have the complete 3D data available right from the start of the project – and the MTF product configurator offers this service.

Again, all the desired features, such as dimensions, infeed and discharge heights, belt specifications, drive unit, base frame and some extras can be selected step by step. The configurator guides the user through the individual stages of the program and can be operated intuitively. If required, a help function is available for each input field. In addition, a plausibility check is carried out parallel to the respective input.

After configuration, the user receives both a complete 3D drawing in all common CAD formats and a PDF data sheet including all relevant dimensions and specifications, as well as a preview drawing in which the model can be rotated or sections can be placed, for example.

This data sheet can also be forwarded directly to MTF Technik in order to quickly receive a detailed quotation for this selection. Once configurations have been made, they can be saved to an individual account and called up for further applications and easily changed again.

As before, the configurator can be accessed via the red tab on our website or simply click here: MTF Technik | Service | Produkt Configurator . If you have not worked with the configurator before, you will also find general tutorials there for getting started and for the individual functions.

Energy efficiency of the drive motors according to EU regulations

28.05.2021

The current regulation regarding the energy efficiency of electric drive units will be repealed and replaced with effect from 1.7.2021 by Regulation (EU) 2019/1781 laying down ecodesign requirements for electric motors and speed governors. The new regulations will then also apply to smaller motors with a power between 120W and 750W.

MTF Technik has always offered very efficient drive units. Depending on the type of drive unit selected, we use motors from 80W in our Multi-Tech conveyor belts. This is made possible by the use of highly efficient planetary gears, such as those used in the internal drive units as well as the drum motors. The I-Tech small conveyor belts are usually equipped with motors with an output of 90W.

Our separator drums are equipped with motors with a drive power of 87W as standard, the drive power of the separator attachments and multi-separators is 50W. These above mentioned motors have such low power ratings that they are not even considered by the new regulation. If stronger motors are used, they will be delivered with energy efficiency class IE2 or IE3 - depending on the desired manufacturer of the drives - by the above-mentioned deadline at the latest.

Our aim has always been to find the best possible and most energy-efficient overall solution for our customers. This means an intelligent optimisation of the entire drive train, starting with the control of the drive - e.g. via a frequency converter, a cycle switching device or a higher-level control system - to the motor, the gearbox and the low-friction design of the actual conveyor belt. The consistent reduction of friction enables the use of smaller drive powers and also avoids abrasion and wear.

Feel free to contact us. We will be happy to advise you on this topic!

New major order for conveyors in injection moulding industry

17.05.2021

A renowned German manufacturer of technically sophisticated plastic articles for a wide range of industrial applications has again placed a large order with MTF Technik. Meanwhile, the consignment includes a total of 169 conveyor belts and 3 separation drums. Currently, 350 devices from MTF Technik are in 24/7-operation in this company.

The current order is for custom-made products that have been explicitly designed for different types of machines and applications. This ensures that all produced components are smoothly transferred from the machine with the dropout switch integrated in it and conveyed for further processing. The exact adaptation prevents components from unintentionally jumping out of the process and landing on the floor.

Would you like more information about our various solutions for the plastics industry? Then just have a look here.

Recent case studies from the plastics industry (Industry Solutions)

10.05.2021

Currently realised projects from the plastics industry (partly clean room) with tasks from the area of conveying and buffering with our individually developed solutions are available here: Industry Solutions/Plastics.

Pleas do not hesitate to contact us in case of further questions via info@mtf-technik.de or phone +49 2261 9431-0.

MTF Technik receives new certificate for climate-friendly energy supply

13.04.2021

MTF Technik has received a renewed certificate for climate-friendly energy. Since October 2017, our company has been completely supplied with climate-neutral, environmentally friendly energy mainly from renewable sources (0% coal, oil, nuclear power), thus offsetting 158.18 tonnes of CO2 emissions. Our supplier LichtBlick has once again confirmed this contribution with this certificate.

MTF Technik supports the charity project "Helfende Hände Oberberg"

04.12.2020

In these times, it is especially important to support social organizations - precisely because their fundraising opportunities are limited due to the pandemic.

For this reason we decided to donate most of our Christmas budget to the local project "Hilfe für Nick & Co. - Helfende Hände Oberberg".

This project helps seriously ill and handicapped children and their families in case of financial shortages. In this way important equipment can be purchased, therapies can be carried out, children's wishes can be fulfilled and the families can be supported in their cooperation with official authorities.

Further information about this project of the Ursula-Barth-Foundation can be found here (German language):