As with the underframe type HF 310, the type HF 340 has two gas pressure springs too, which support the steep belt and therefore, provide an easy angle adjustment. The difference lies in the additional substructure of the entire base frame so that higher filling and loading heights can be accomplished.

This makes sense where e.g. the conveyor technology is used at manual work stations and where parts are placed on the belt manually. Here, an ergonomic working height is crucial. This belt conveyor model is likewise applied in many areas where parts from production machines get onto the belt conveyor, and where the transfer heights are accordingly big. This is the case with e.g. many packing machines or automatic test equipments etc.

The conveyor belt illustrated shows a model where parts are removed from a production machine and conveyed to a stainless steel tray, located laterally to the conveyor belt, for optical inspection. One part of the tray is manufactured with a horizontally depositing table and fastened to the upper part of the flat belt. By means of a fender mounted at an angle to the conveying direction, the parts are pushed from the belt into the tray.

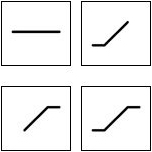

As with all MTF Multi-Tech angled belt conveyors, the belt bend can be adjusted continuously to any level between 0° and 60°. The belt tension stays constant and balanced over the entire adjustment range due to the patented belt tensioning mechanism.