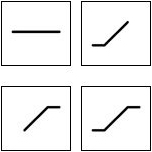

The belt conveyors of type ZL-HF 310 are often used for discharging parts out of machines and feeding them to a subsequent production step. They are especially suitable for steep belt lengths of approx. 2,500 mm and relatively short upper flat belt lengths. The gas pressure springs integrated in the underframe enable a very easy adjustment of the conveying angle. Thus, the z-conveyor technology is especially suited for applications where the disposal or feeding height is to be changed more often (e.g. due to different container heights).

The upper flat belt freely overlaps in forward direction but it can be supported additionally, if required (e.g. with larger loads or longer flat belt parts).

The lower flat belt area lays on the underframe so that a stable, closed frame is created. Hence, even larger conveyor belts can be handled easily.

With this Z-conveyor, the minimum feeding height from the floor to the upper edge of the standard feed hopper is approx. 400mm. If necessary, the underframe of type HB 310, whose flat belt part is placed at a lower position, may be used alternatively. Therefore, lower feeding heights can be accomplished.

Conveyor technology of this design is used in many areas, e.g. to remove parts from production machines such as punching shops, in the plastics and electronics industry, in surface treatment plants etc. Also, Z-shaped conveyors are often used as feeders for components in machines for further processing, e.g. in the food industry or as feeding belt for recycling facilities or grinders.

As with all MTF Multi-Tech belt conveyors, the angle of the Z-conveyor can be adjusted continuously to any angle between 0° and 60°. The belt tension remains constant over the entire adjustment area due to the belt tensioning mechanism patented by MTF Technik. This benefit also enables e.g. a pneumatic or electric adjustment of the angle in order to adjust the delivery height to the process (reduction of drop height).