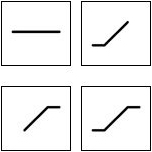

This Multi-Tech Angled Conveyor is a custom-made product. In this case, two parallel steep belt conveyors with an conveying angle of 75° had to be mounted in a narrow space on a common underframe.

This parallel bunker conveyor was designed for a manufacturer of medical plastic parts, in order to feed two production machines with components in a confined space.

All parts in contact with the product are made of stainless steel, all welding spots and connecting joints are completely polished and executed without any seams.

Optionally, a large covered hopper in stainless steel can be integrated for manual feeding. Moreover, extra caps for a failure-free transfer to the following machine can be mounted at the disposal area.

The high transporting cleats are bended forwardly in order to create a shovel effect for a safe transport of the required amount of goods.