L-conveyor belts with a short steep belt area of max. 500mm wide are usually equipped with an underframe, type KB 010. In this version they are used e.g. as chipping conveyor belts in machine tools where the conveyor belt is integrated in the machine frame.

This belt conveyor type is also suited for the application in the plastics industry, in injection moulding machines with low shaft height or in combination with sorting or selecting diverters which are mounted below the tool and thus restrict the available space.

L-conveyors of this type are also used to convey material or parts out of a machine to a subsequent conveyor belt that is arranged at a right angle to the machine.

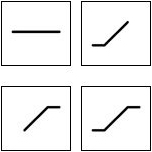

The underframe of type

KB 010 makes it possible to lower the flat belt area of the angled belt to the floor. Thus, lowest delivery heights, e.g. also under packing machines or in narrow machine shafts, can be accomplished. The flat belt thereby ìhangsî in the underframe profile where wheels are attached on the face side, at the belt inlet, and laterally at the belt outlet.

The steep belt part protrudes freely in forward direction without frames, or the like, blocking the way. Hence, the belt conveyor is particularly suited for the conveying of parts to small boxes or at low delivery heights. The adjustment and locking of the angle takes place via two screws in the bend covers. As with all MTF Multi-Tech angled belt conveyors, the conveying angle can be adjusted continuously to any angle between 0 and 60°. Thanks to the patented belt tensioning mechanism, the belt tension always stays constant.