The belt conveyors of type GL-LD 120 are characterised by the stable underframe with closed base frame. The supports are laterally attached to the conveyor belt and enable an easy height or incline adjustment. This design is mostly used for belt conveyors with a length of up to approx. 5,000mm.

The conveyors of this type are often used in the plastics industry, e.g. for the feeding of medium size grinders, where the delivery area of the conveyor belt reaches into the grinder shaft and the feeding area must be mounted at an ergonomic height.

To protect the grinder, these belt conveyors can be optionally equipped with metal detection devices. They can either be one-layer surface metal detectors integrated in the belt body or tunnel detectors which surround the entire conveyor. Through the associated controller, signals of the grinder (e.g. in case of overload) can be processed too. Hence, an optimised batching can be accomplished.

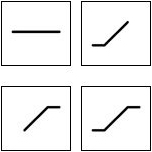

In order to take advantage of the width of the grinder shaft in the best possible way, the conveyor drive is normally installed at the belt inlet, i.e. it is pushing. Alternatively, drum motors or drives installed inside may be used which laterally protrude the conveyor belt frame only a little bit.

In many cases, hoppers are attached to the feeding area of these belts, to be able to feed in a higher amount of parts in one go, which then are batched step by step.