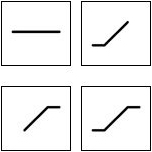

The belt conveyors of type GL-IE 010 are particularly outstanding by their underframe which is equipped with a gas pressure column adjustment with a ball guide in the stroke. Therewith, the entire conveyor belt can be adjusted in height and incline by minimum effort.

This is helpful, when the conveyor belt is to be adjusted frequently to different conditions, e.g. when used at various machines, or when parts have to be conveyed in containers or cases of different heights. In addition, it is used when the adjustments have to be done without personnel or available auxiliaries/tools (e.g. during night shifts or weekends).

Belt conveyors of this type are very often used to dispose of products from production and assembly machines. For this purpose, additional attachment hoppers can be mounted to ensure a problem-free part transfer.

Also, separator attachments are oftentimes attached to this conveyor belt type, in order to e.g. separate plastic parts from the sprue in steps at the injection moulding machine, directly after the production process.

The one-sided installation of the underframe on the guiding profile brings the belt conveyor into a direct, sideward position to the production unit.

The version GL-IE 020 represents the cost-efficient alternative, which is also attached on one side, but with one fixed pipe instead of the gas pressure column support . It is used if the height of the conveyor belt is adjusted only in rare occasions.

The version is particularly recommended for smaller conveyor belts with a length of up to 2,000mm and a width of up to 400mm.