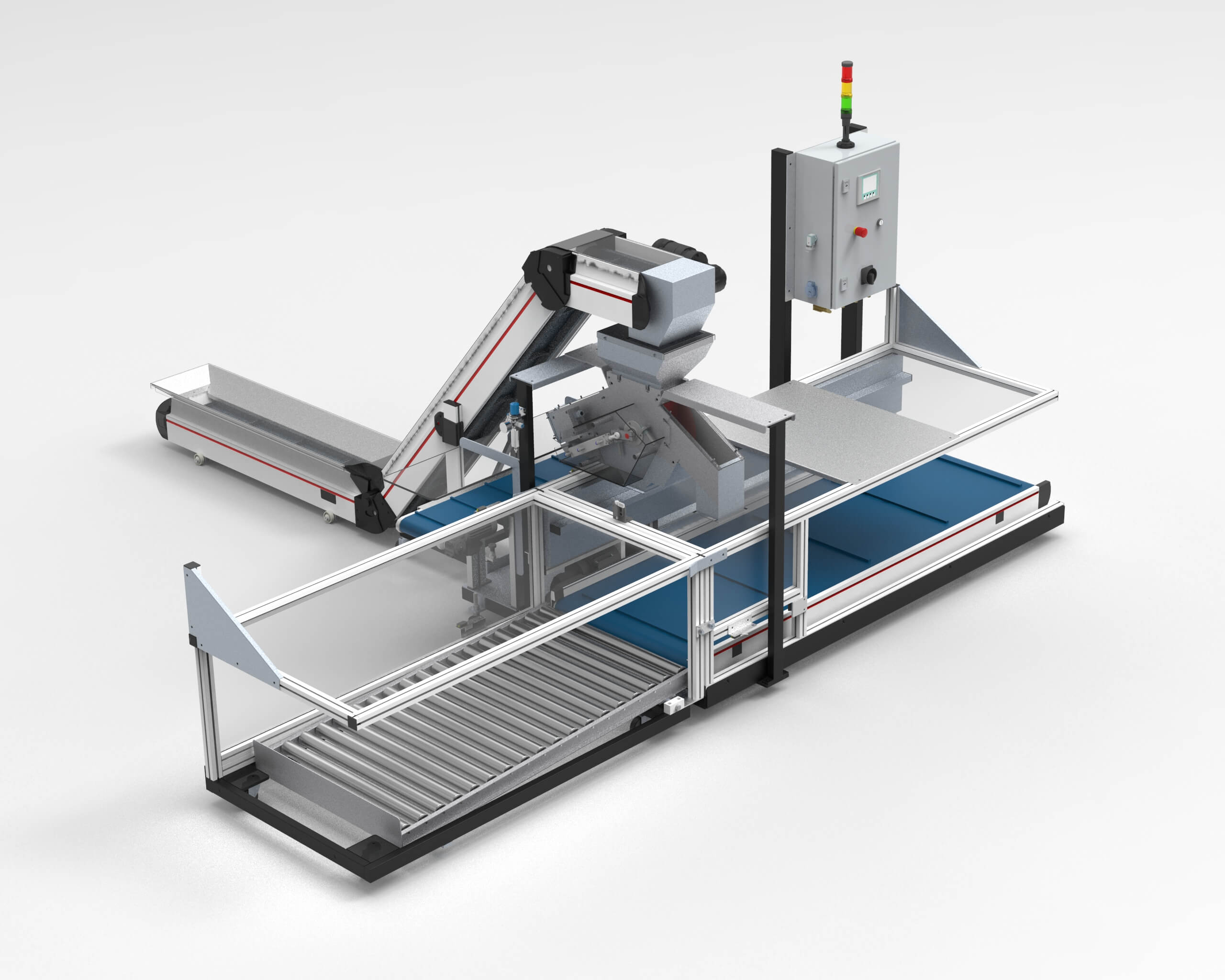

Solution: Linear buffer with angled conveyor belt and roller conveyor, incl. 3-way reject chute for QA

-

Use of an angled conveyor type NL-HE 020 with PU belt incl. corrugated edges and covers to guide parts to the centre of the conveyor and to avoid parts jamming.

-

Installation of a PET belt cover in combined pluggable/slewable design.

-

Transfer hood at the conveyor outlet to guide the parts into a pneumatic 3-way reject chute with patented mechanism to avoid jamming of small parts.

-

The two zones above the container buffer conveyor can be controlled via the switch in order to prevent dumping cones in the large bins or, optionally, distribute into two small bins parallelly

-

The third outlet of the chute is used for discharging the QA-parts. For this purpose, an I-Tech small conveyor belt is mounted in parallel next to the buffer system, on which the separate bins are placed and buffered.

-

Integration of a Siemens S7 incl. interface to the production machine for controlling the entire process.