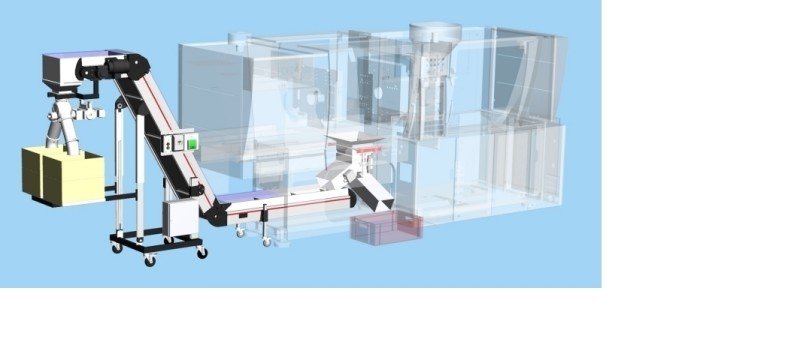

In this version, the reject chute is mounted below the tool with an outlet to the operator side and one downwards, in direction of the clamping side of the injection moulding machine. The separation chute discharges sprues and scrap parts into a box at the operator side, and the good parts are transported by a conveyor.

In the illustration below, the Z-angled conveyor is equipped with a further diverter valve at the end. This diverter valve switches after reaching a certain number of parts in the box, thus serves as buffering device.