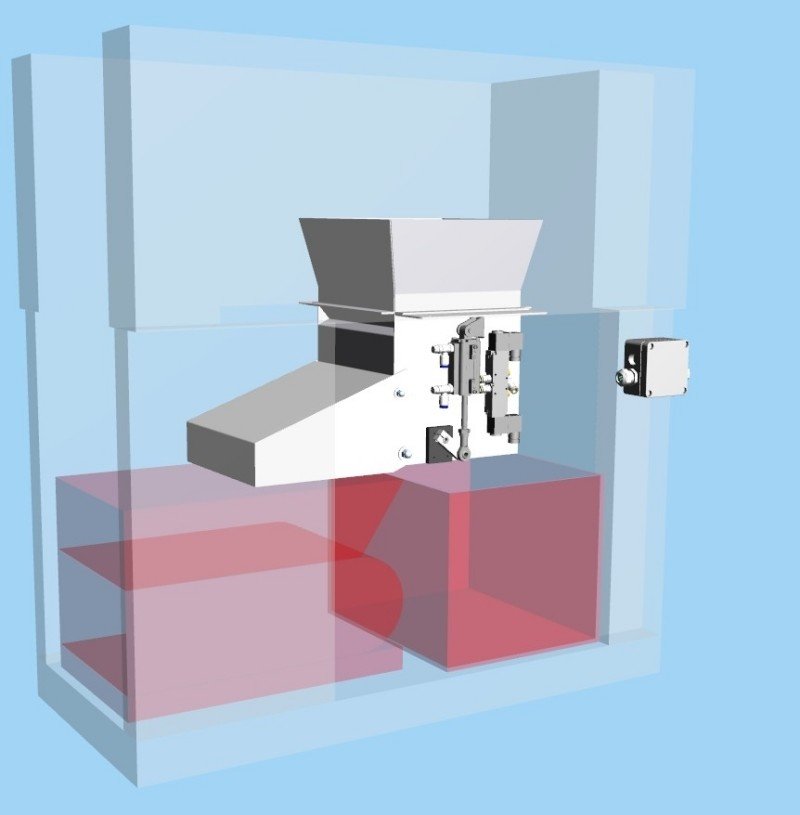

In this version, the reject chute is mounted alongside within the machine base of the injection moulding machine. Start-up parts, sprues and runners fall vertically downwards into a box which is positioned directly below the tool in the machine base.

The good parts are handed over to a conveyor which is mounted alongside within the machine base. The drop out chute is closed at the front side, therfore the parts fall vertically on the conveyor and do not jump from the conveyor. Moreover, the conveyor is covered with a plate after the dropout opening of the reject chute.

The parts are directed via a plastics changeover flap, in order to keep the gaps as small as possible. The flap is switched via a pneumatic cylinder, which receives pressure gas from a two-way controlled pneumatic valve. The stop positions of the cylinders are read via reed contacts.